My heart and my mind are still with the clocks and I just finishing a new design.

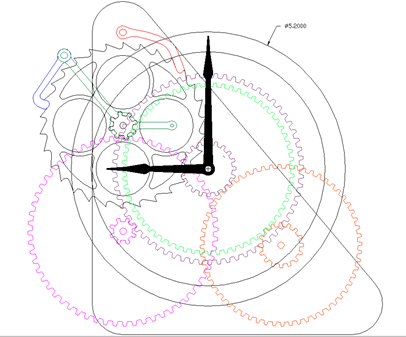

My new clock, still in paper but very very advanced in the design has a name: Pythagoras and here is a pic of the basic drawing:

One of the big problems of the wooden clocks is the precision. They are really affected by temperature and humidity. My friends are always asking for nice clock and a the same time with precision. Wood, brass and gravity will never make a high precision clock although they are really pieces of art that require a lot of dedication, love and tons of patience but common people do not understand this. When I show my clocks the first thing most people say is “How beautiful!.. etc, etc. But a second later the big question: How precise is it?

So I decided to mix electronics and art and create a Microprocessor controlled wooden d clock. This clock will be driven by a Solenoid that will tick each 2 seconds The Escape wheel is a ratchet with 30 teeth. The solenoid has a total movement of 4 mm that will be converted in a 12 degree rotation of the wheel. The other design characteristic is that the distance between centers of all the wheels is 2” and the position of the wheels forms almost a triangle rectangle. This is the reason for the Pythagoras name of the clock.

As usual I will start with a test stand for the driving mechanism: The escape wheel, the solenoid and the microprocessor, and I will be sharing with you all the leanings. As I am traveling a lot for working reason this will be slow, but you can be sure that I will finish this clock.

See you soon!

No comments:

Post a Comment

Please be aware that any comment with commercial links will be immediately deleted and declared as SPAM.

If you want to advertise in my blog please contact me to agree in a fee and i will be happy to add your link in the side bar.