I am an experienced 3D drafter. In my day to day work I use AutoCAD, Invertor and SOLIDWORKS. I can switch from one to other without major effort. These programs are all very good and well recognized but at the same time very expensive for personal use. All these programs require to have a computer (powerful) loaded and with the licenses. For big projects you need a server to work on collaboration mode and the price of the license per user is several thousands of dollars a year if you need to keep the software up today.

I have tested many open source 3D drafting programs and also Google SketchUp; some of them pc residents and some cloud based. I did not feel confortable or productive with any of them.

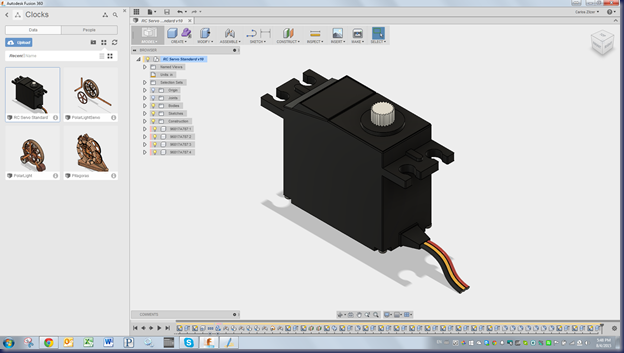

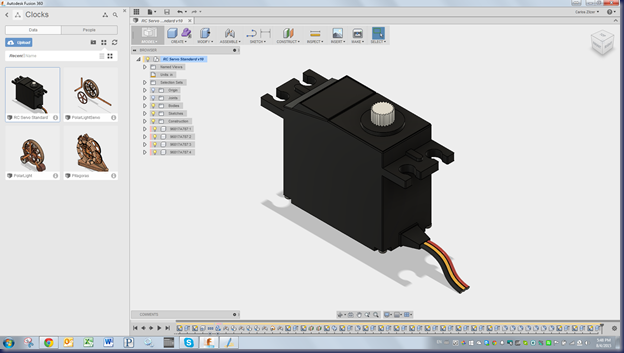

This weekend I downloaded the demo version of Autodesk Fusion 360 and after a couple of hours I registered it and I I fell in love with it. I transferred some of my clocks models to Fusion 360 and started to play around. Then I decided to make a first full drawing of a part, in this case a RC Servo that I will use in a clock. Knowing Inventor the learning process was a piece of cake.

The other good news is that Autodesk Fusion 360 has a very interesting offer: A free 1-year startup license is also available for hobbyists, enthusiasts, makers, and emerging businesses that make less than US$100,000 in revenue per year. At the end of 1 year, you can reselect the startup entitlement or transition to a commercial entitlement.

After finishing the drawing it is necessary to use a program for generate the CAM to be able to mill or fabricate the parts. Mastercam is an excellent program but too expensive for personal use. I don’t know any good machine shop that does not use Mastercam. This program is the standard.

I use BobCad-Cam V26 as CAM postprocessor because I bought it during an offer they had last year at a reasonable price, but I need to convert my work to DWG or STEP in order to run BobCad. The CAD part of BobCad V26 is not as good and flexible as other programs. I know they made a lot of changes in version 27 and probably is much better now but I am not willing to pay more for something I use for hobby and not for work.

Fusion 360 has CAM as part of the package and also has the postprocessor for MACH3 that is the software I use to drive my small CNC. Now the work will be straightforward: Model – CAM – Mill with the same platform.

The next step will be to create a model of a sprocket or wheel and run the cam to learn and test the results with my small CNC machine.