For my next clock I want to make some innovation in the driving system. My idea is to design and build a simple DC motor with wood, some permanent magnets and a coil. My expectation is to make something of very low power consumption to be ablate to run the clock on batteries .

A simple DC motor is what is called a pulse motor. A disc with magnets is forced to rotate when the magnets are facing an electromagnet and the electromagnet is activated at the right time to create a magnetic force that can either attract or repel the magnets. The timing to switch on the magnet is given by a reed switch or any other sensor like another coil. For this prototype I used a reed switch and the coil form a damaged contactor that was changed in the central air conditioner of my house. This kind of motor normally run at high speed and there is no speed control except by adjusting the voltage of the battery. The problem is that as the battery loses power the speed will slower.

For a clock drive we need a constant speed, so I had to add some kind of speed regulation. In the case I made my design based one that was part of all the steam engines that is the centrifugal governor or speed regulator.

This tiny motor runs at 750 RPM when the voltage is above 5 volts and will keep the speed from 5 volts to 24 vols. That is the maximum voltage I can use in the coil before burning it

The video below shows the prototype running and explains the principle. This one runs with 4 AAA batteries.

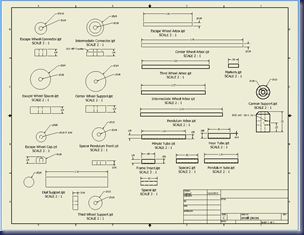

Now I need to work in a nice and robust design to be used as a real wooden clock driver. The final design will use a pickup coil and transistor to drive the main coil. It will also use four 1/2” Neodymium magnets and a regulator design very similar the the picture below