A little bit of history and theory:

After a couple of months out of my garage due to colon cancer surgery (fortunately cancer is gone!) I am slowly acquiring strength and returning to my garage to continue with passion. I still cannot return to my normal work activity until a couple more months so I can dedicate a lot of time to the development of my hobby.

Conical pendulum clocks are part of the clock history but as they are not easy to implement you don’t see too many around, and as far as I know there are no wooden conical pendulum clocks.

The concept was patented by J. C. Briggs in 1885 but the French already built conical pendulum clocks some of them as far as 1869

This is the Briggs Rotary pendulum clock:

And tis is a typical French conical pendulum:

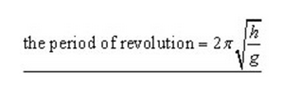

The angle and the height of the pendulum bob is related to the period of a revolution by the following formulas (this is for an ideal pendulum):

The rotational speed will be slower for a longer pendulum and for a fixed length “T” a smaller radius “r” will make the pendulum to turn slower because the height “h” will increase as the radius decreases.

Conical clock are usually driven by a windup system with constant force springs but my idea is to combine the concept of the pulse motor with the conical pendulum. I also wanted to make a one second period pendulum to be able to build the wooden clock with reasonable size wheels. in this case I will replace the escapement wheel by a set of crown wheels. Clyton provided me with some draft drawings of a wooden conical pendulum clock. I will try to use his basic initial design adding my motorized conical pendulum and as much of my creativity I can to explode and convert his original idea in a reall wooden conical clock.

The Motorized Conical Pendulum Prototype:

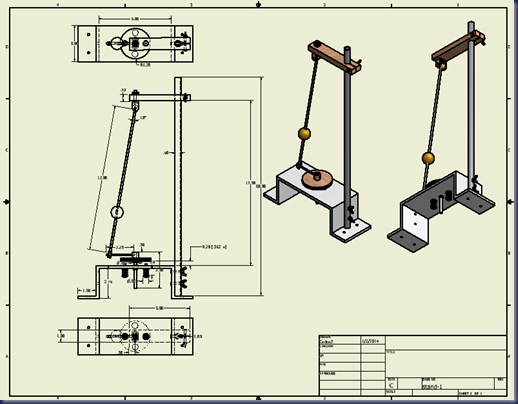

Before staring the construction of the clock I needed to make a lot of experimentation so I designed a test stand to first test the motor without pendulum and then to test the pendulum.

The original design had a wooden rotor with 4 Neodymium magnets and two coils, one for pickup an the other as an actuator. The electricity induced in the pickup coil when one of the magnets was passing trough the core of the coil generates an impulse that is used to turn on a transistor to make the current to flow in the actuator coil. This will create a magnetic field to attract or repel (depending on the coil orientation) the magnet, this will create a rotary motion.

At the end and after many tests I decided to eliminate the pickup coil and use an optical switch activated with an optical cam. In this video I show the first version of the test stand. Here it is is running faster than 1 sec/rev. It took me almost three week to get a perfect working model.

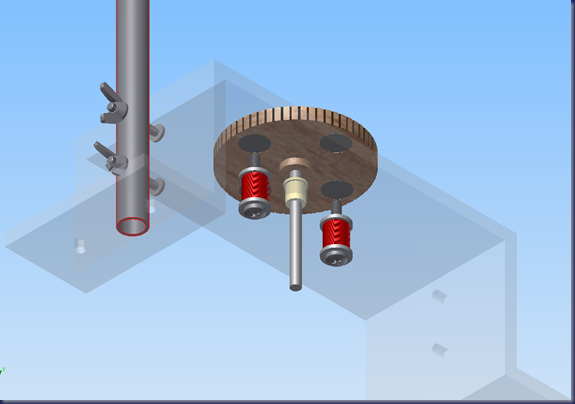

The final design is the result of lots of modifications and tests. But the important thing is that now I made all the learning and understood all the necessary to make a final working design in wood. I added ball bearings, I changed the height and the design of the pendulum rod. I found the optimal design of the optical cam. To optimize the development speed I used acrylic and aluminum to make most of the parts and this was a very good opportunity to learn how to work with different materials with my CNC.

My CNC milling aluminum:

The rotor made with acrylic and aluminum:

In this Video I show the final version of the Conical Pendulum, running at 1 second per revolution.

Art or Technology?

The trick to make the motorized conical pendulum to run at the correct speed is to set the motor to deliver the exact amount of torque for the pendulum to do its job. If too much torque is applied then the pendulum will reach to the top angle due to the centrifugal force but the motor will continue to accelerate. If not enough torque is provided then the pendulum will eventually stop. Some people have asked me why I did not use a microcontroller like the Arduino to monitor the speed and adjust the torque. My answer is that using this high tech will make the pendulum a dummy device, I could use a simple servo motor controlled by the Arduino to move the clock or buy a Chinese clock motor to drive the wooden clock! I like the art and the challenge to make the things to work in the simplest way possible. The old clock makers like Briggs did not have an Arduino and they were capable to design a very accurate time keeping machine. My goal here is to find an electrical substitute for the constant froze spring and this, from my Point Of View, is Art!

No comments:

Post a Comment

Please be aware that any comment with commercial links will be immediately deleted and declared as SPAM.

If you want to advertise in my blog please contact me to agree in a fee and i will be happy to add your link in the side bar.